Innovating Across Decades: A Technology Ahead of Its Time

As ETP Transmissions celebrates 40 years as a company, the innovation that took the company out of the starting blocks is still as relevant as ever. The first hydraulic hub-shaft connection, long known as the “ETP-CLASSIC”, was sold in 1973 – more than ten years before the company saw the light of day. With a groundbreaking design, built on hydraulic principles, it came to shape the subsequent journey for the corporation.

– We like to say that Pascal came up with the idea and we put it to work. And, luckily, the industries were as enthusiastic as we were, Niclas Rosberg, CEO at ETP Transmissions, says.

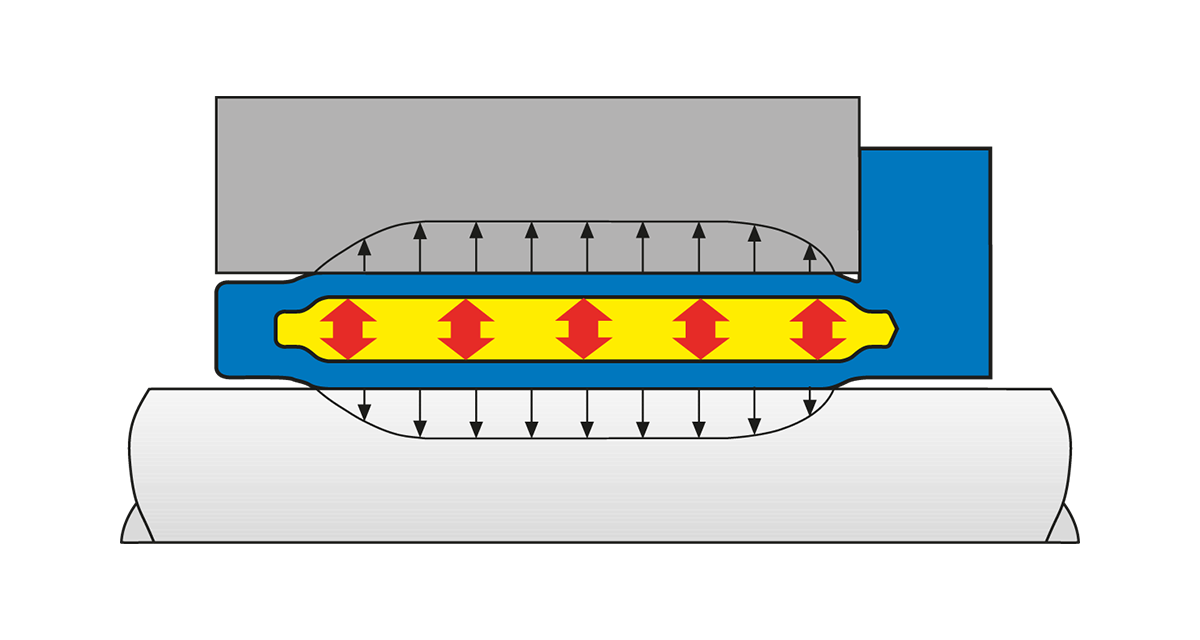

In the early 1970s, the advent of advanced manufacturing machinery prompted a surge in demand for innovative hub-shaft connections suited for the new era of power transmission. While inventors in other parts of Europe focused on mechanical transmissions, the Swedish entrepreneur Kjell Landeaus had a different, in many ways more innovative, approach. Inspired by the principles of the renowned French mathematician Blaise Pascal, he engineered a product that in large consists of hardened double-walled steel sleeves welded together to create a hollow chamber that can be filled with a hydraulic pressure medium. By applying hydraulic pressure, the chamber expands uniformly against both the shaft and hub, ensuring a very accurate and rigid joint from which the power is transferred through friction – providing groundbreaking concentricity and repeatability. The original patent was developed for Försvarets Fabriksverk (a part of the Swedish Armed Forces), but soon the founders started to look for civil applications for the product and ten years later it became a cornerstone in the offering for the then newly formed company ETP Transmissions AB. Since then, the hub-shaft connection has come to be known as the ETP-CLASSIC and has been followed by many renditions aimed at different segments of the manufacturing industry.

“We recognized the greatness of using the hydraulic principles and saw an opportunity to build a company around the concept. Until then, the industry had not seen the kind of precision for hub-shaft connections that we could provide – especially not in combination with how reliable the couplings are over time. To ensure minimal leaks, we developed our own type of 'clay' where the viscosity makes it much harder for it to escape the structure compared to other mediums”, Niclas Rosberg says before adding:

“Our hub-shaft connections are more expensive than those based on mechanical joints, but when those working in the industry have had the chance to try our solution, there's rarely any discussion about which they prefer. Especially these days when we have made the couplings incredibly easy to attach.”

Kent Månsson, Börje Peterson and Anders Samelius showing the first hydraulic sleeves from ETP.

We recognized the greatness of using the hydraulic principles and saw an opportunity to build a company around the concept

Efficient and easy mounting

While ETP’s first hub and shaft connection required almost the same intricate attachment process as mechanical transmissions, the company has worked hard to make the process easier and more user-friendly. ETP-TECHNO was launched, soon followed by the ETP-EXPRESS, leveraging hydromechanical principles to make the attachment process easier. Now a single, hand-tightened screw could create an internal pressure of approximately 1000 bar and make any connection perfectly precise. In combination with new methods to develop the products, among them electron beam welding to guarantee stronger structures and exact similarities between each product, ETP’s hub shaft connections gained even greater market traction.

“Our mission is to simplify operation for industrial installers and service and maintenance staff. While the ETP-CLASSIC changed the packaging industry with its groundbreaking precision, The ETP-EXPRESS offers a significant advantage in sectors like PET bottle manufacturing where reducing downtime is crucial, thanks to the remarkable ease of the mounting”, explains Niclas Rosberg.

A bright future

Today, almost 50 years after its conception, the ETP-CLASSIC is as relevant as ever. New manufacturing industries have discovered the many advantages of never having to worry about the precision, duration, and repeatability of their hub-shaft connections, making the different renditions of the product find new applications. In the early 2000s, ETP introduced the ETP-HYLOC for heavier industrial applications and the ETP-OCTOPUS, designed to be used in highly automated environments. More recently, the company has embraced stainless steel for corrosion-resistant variants suitable for medical and food and beverage sectors, where stringent hygiene standards are imperative.

“We’re constantly trying to stay ahead of the game and have solutions when the market is ready to take a step in a new direction. By using stainless steel, we have opened a new market that we only have started to explore the limits of”, Niclas Rosberg says before concluding:

“While all our Hub-Shaft connections share core principles with the ETP-CLASSIC, we've tailored our technology for diverse markets. Generally, it can be said that the more important precision and repeatability, the higher the demand for our solutions. And as machinery evolves towards compactness, speed, and automation, our hub-shaft solutions are poised to remain sought after well into the future.”

.

The principle

Pascal came up with the idea - we put it to work!

The method employs an elastic mass that expands within a device when subjected to pressure, creating friction between the shaft and the object, holding them together. Unlike using a wedge for example, which relies on direct pressure, this invention uses pressure and elastic mass to achieve friction, preventing the object from spinning freely on the shaft. The advantage of this is that when using a pressure medium with liquid, you always have the same pressure since the force comes from all directions, leading to outstanding precision.

See all our precision connections